- Products

-

-

Products

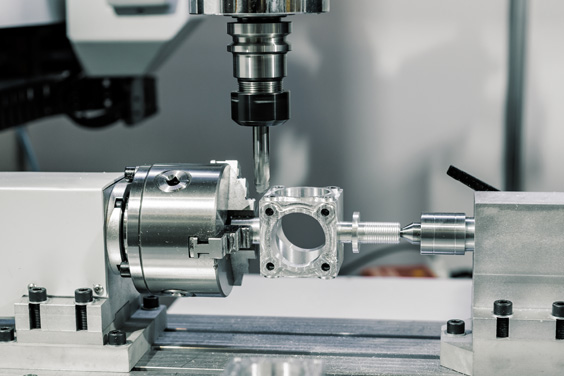

- Turning

- Milling

- Grinding

- IoT

- SPM

- 3D Printer

- Laser Cutting

- Foundry

-

Turning

-

-

- Services

- Industry

- News & Media

- About Us

-

-

About Us

- Our Brands

- Our Team

- Clientele

-

-

- Contact Us

-

-

Contact Us

- Network List

- Enquiry

- Career

-

-

-

India

India

China

China

Europe

Europe

.svg)

.svg) Download Brochure

Download Brochure