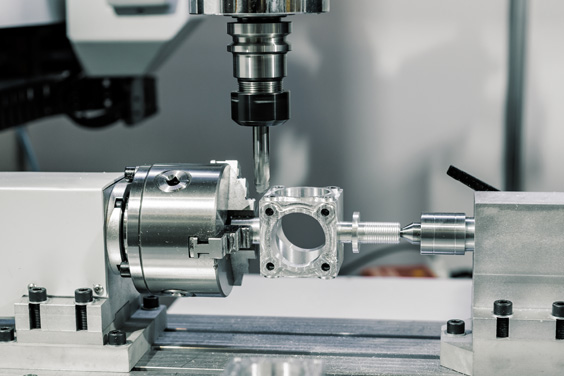

The Double Column Vertical Machining Centers are designed specifically for Heavy Duty applications along with full milling capabilities. The DC (Double Column) Machines having Rigid structure, High speed machining with incredible efficiency. These machines are designed to achievehigh accuracy and productivity. The machine is best suited for machining large sized components for Automobile, Die Mould, Aerospace Components, Earth Moving, Mining, Railways, Energy, Printing & Pattern Making Sectors.

• Highly Rigid Structure, X-axis configuration to the table, Y & Z-axis configuration to the spindle.

• Hardened ground LM roller guideways& Precision Ball-screws for X, Y & Z-axis

• Programmable Automatic 90 deg. Head / Universal Head (with Parking Stations) (Optional)

• Wider Gap Between Columns

• Direct drive/ Inline Spindle

• Spindle Chiller Unit for decreasing spindle thermal displacement.

India

India

China

China

Europe

Europe

.svg)

.svg) Download Brochure

Download Brochure