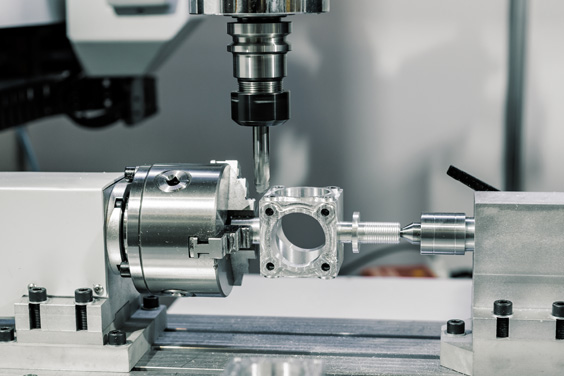

The DTC-400 XL is compact and powerful, loaded with BT-30/BBT-30 spindles. The machine is built with optimally designed structure to take care of cutting forces, cushioning high speed and accurate tapping. The machine is equipped with roller type LM guideways for delivering better rigidity and superior performance.The DTC-400 XL is equipped with High Speed Pocket tilting type Automatic Tool Changers with 16 / 24 tool capacitywith chip to chip time of 1.7 / 1.5 sec, designed based on the machine size and suitable application. With a rigid structure and high speeds one can achieve high accuracy and productivity on these drill tap machining centers.

India

India

China

China

Europe

Europe

.svg)

.svg) Download Brochure

Download Brochure