Job Summary

Coordinates, organizes, and oversees all activities involved in the identification, acquisition, production, and distribution of the company’s goods.

Job Responsibilties

1. Lead a team of Process Engineers & responsible for the overall strategy and execution of Process Engg function as well as the planning and directing of activities and operations of the business at our vendors’ premises.

2. Optimizes productivity by designing, implementing, and testing new process.

3. Plan and manage process-improvement projects to improve quality, reduce cost & lead time and support production methods and processes for manufacturing excellence.

4. Generate production and assembly procedures using SOLIDWORKS, facilitating smooth transition from prototype build to full-scale production.

5. Leverage SPC and statistical methods for evaluating production processes and development projects.

6. Responsible for and ensuring process compliance.

7. OEE improvement & analysis of in-house rejection, COPQ & preparation of detailed action planned execution through the PDCA cycle.

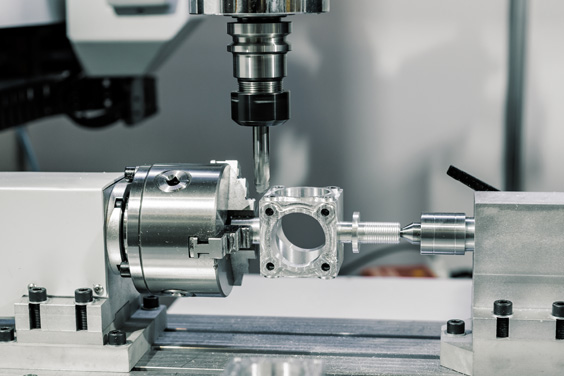

8. Oversee Complete CNC Programming, fixture setting, try-outs, process mapping, preparation of control plan, FAI, FMEA, APQP for the new component as per the schedule and making the best possible improvements.

9. Involve in Capacity planning, Plant facility budgeting, complete plant layout finalizations.

10. Ensuring implementation of TPM (5S, Kaizen,Poka-yoke,Kanban) for higher productivity by reducing various loss at vendors premises too.

11. Implement a KANBAN system for manufacturing to reduce wasteful production activities.

12. OEE improvement & analysis of in-house rejection, COPQ & preparation of detailed action planned execution through the PDCA cycle.

13. Assesses compliance with applicable safety and quality standards.

14. Conducts risk assessments.

15. Min 5% cost reduction through process improvement of Manufactured parts.

Skills Required

1. Technical Knowledge

2. Ability to identify, assess and solve problems using Statistical Tools.

3. Influence team to bring improvement in existing practices.

4. Proficient with computer and information technology

5. Excellent analytical and math skills

6. Strong written and verbal communication skills

7. Reading drawing & Solid CAM/ Auto CAD preparation/ SAP.

8. Leadership

9. People Management

Pre-requisites

1. Robust Manufacturing Process Knowledge, Jigs, Fixtures, Latest cutting Tools, CNC Milling, Boring, Turning, Grinding, Latest machining trends, Toyota systems, Heat treatment, and Surface treatment.

2 Able to Guide team, Improve manufacturing process, Cycle time reduction, Process sheets, CTQs, Inspection, productivity improvement, and process capability studies.

3 Capacity calculation, CNC programming, Hands-on Experience, OEE.

4. Ability to Interact/ Support/ Handhold/ develop vendors effectively.

5. Ability to “Build an empowered & enabled high precision Supply Chain Eco-System”.

India

India

China

China

Europe

Europe