- Products

-

-

Products

- Turning

- Milling

- Grinding

- IoT

- SPM

- 3D Printer

- Laser Cutting

- Foundry

-

Turning

-

-

- Services

- Industry

- News & Media

- About Us

-

-

About Us

- Our Brands

- Our Team

- Clientele

-

-

- Contact Us

-

-

Contact Us

- Network List

- Enquiry

- Career

-

-

-

India

India

China

China

Europe

Europe

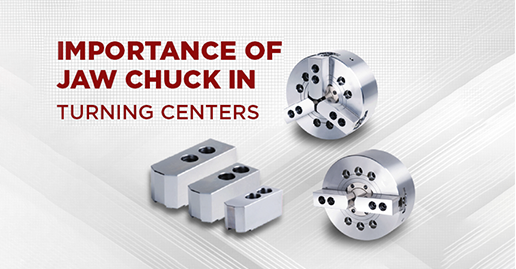

Hard jaws are usually used on rough material surface.

Using soft jaws on rough surfaces may create

impressions on clamping surface of soft jaws.

Hard jaws are usually used on rough material surface.

Using soft jaws on rough surfaces may create

impressions on clamping surface of soft jaws. Soft jaws are made from soft steel, bored to

grip a part at particular diameter.

Soft jaws usually don't leave an impression on

jobs.

Soft jaws are made from soft steel, bored to

grip a part at particular diameter.

Soft jaws usually don't leave an impression on

jobs.