Precision CNC machining centers

Whether you require brass fittings or supplementary metal components for the aerospace, energy or medical industries, this blog will let you understand your needs!

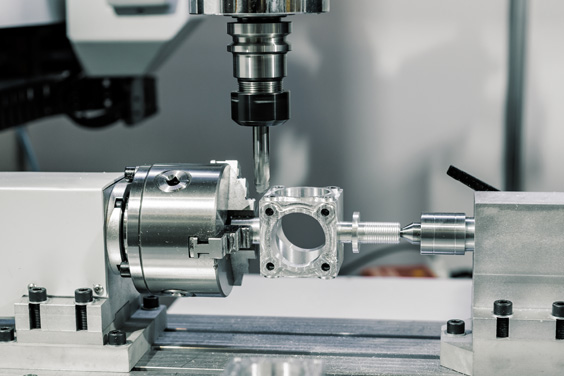

Many such industries assimilate the use of precision CNC machining for critical components along with robotics to manufacture precision products. Likewise, precision CNC machining is a reliable approach to ensure quality and accuracy in the component manufactured. Be it manufacturing parts for aerospace, die & mould, energy or defence, precision CNC machining along with the right metal can help you achieve the desired outcome.

Finding the right CNC machining center

When selecting a machining center to use for precision CNC machining, it is vital that you look for the one that could serve your current requirement. You must obtain a guide or manual that will help you determine you actual need. If possible, seek assistance from technical experts and get your queries sorted.

AMS machines are designed to suit the need of every industry. Every AMS machine is capable of manufacturing components with a high critical tolerance. Given the high demand for custom-made machines; AMS builds robust CNC machines that suit the needs of its customers. Besides, on request, AMS also provides additional features alongside its machines.

Depending on what product is required to make critical components, using the right machine can help your company manufacture several items by precision CNC machining. For achieving a customized critical tolerance in a component, a company should select custom-made AMS machines with tooled-up applications.

AMS machines, both standard and custom-made, can manufacture precision components from materials like stainless steel, titanium, aluminium and alloys. However, to achieve augmented results in precision manufacturing of components, there is a need for the right type of layout and prototype to make perfect components each time.

Vital features that one must look for while purchasing a machining center

- The manufacturer should possess sound technical knowledge about the industry and the machines they have on offer.

- They must be in a position to leverage your business strategy by providing crucial market data.

- They should have a diverse experience of catering to all industrial sectors.

- Engineers should have strong support network and domain knowledge about the machines.

So whether it is a specific component or a tooling assembly, the right machine should be picked to do the task. If you want to experience improved quality and consistent design accuracy, AMS machines can help you achieve this objective. For more details about AMS machines and tooling solutions, visit

www.acemicromatic.net

India

India

China

China

Europe

Europe