Profitability in the machining world comes down to minute details. A quick tool change can make all the difference in your manufacturing processes which has a direct impact on profitability.

When there is any discussion on productivity, it is always on the cutting speed, but total machine utilization adds to actual efficiency. A slow tool changing system can drastically affect productivity. There are faster tool changing options available and the best one is the VDI tool changer.

With a swift change, tooling solution processes like measuring, set up and tool changing can be increased by a critical margin.

It is known that turning technologies like CNC sliding head and lathes require quick tool indexing, but usually, have lower utilization than machining centres due to tool change and set-up time.

When there is no Automatic Tool Change (ATC) in the machine manual, quick change is utilized. It ensures more machining happens than idle open-door time. There are many benefits to using quick change. Released over 20 years ago, VDI has been considered the most widely used on the turret.

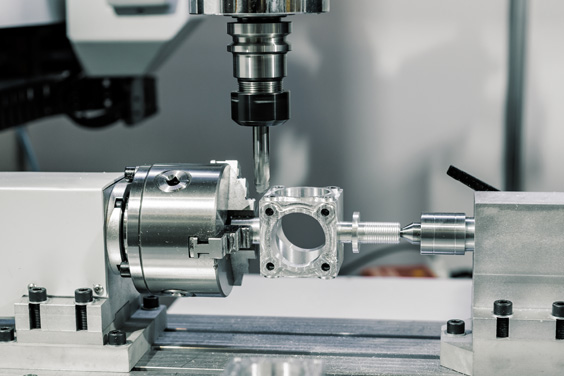

The tool is held in place by a mating part with teeth housed inside the turret. With the help of an Allen wrench the locking screw, which is on the face of the turret, is tightened that clamps the tool to its place securely.

A pin on the mounting surface keeps the holder from twisting which thereby assures a good clamp. You can verify the straightness of the VDI tool holder during mounting by twisting the screw and adjusting the straightness.

Advantage of VDI

- Lesser setup time as there is only one screw to tighten the holder

- It is cheaper than a BMT tool holder

- Easy to operate as you can adjust the straightness and precision of the holder

Additionally, tool holders can be pre-set away from the lathe on a pre-setter since VDI capable turret ensures accurate and rigid positioning of the VDI tool holder.

The VDI tool holder retention system provides an accurate and rapid method of fixing tools to the turret plates. The round serrated tool holder shank fits into tool pockets located on the face or edge of the tool plate clamping mechanism using a single Allen wrench to achieve precise, rigid and secure locking of the VDI tool holder.

The hardened and ground serrated wedge (see the sample picture) accurately locks the tool holder into position and securely pulls it back to the surface of the turret. Typical changeover time for a pre-set VDI tool holder is less than fifteen seconds!

VDI tool holders also come in static and live (motorized) versions which allow a CNC lathe to perform milling and radial drilling operations in one cutting cycle!

India

India

China

China

Europe

Europe