Insert life, cycle time and machining cost by best programming method

As we all are aware that every line of CNC Turning part program will have functional instructions to machine elements, like spindle rotation, axes movement (linear or circular) and miscellaneous function like coolant on/off, door open/close, chuck open/close, tailstock forward/retract etc, here we will discuss on shaft or long contact time tuning components:

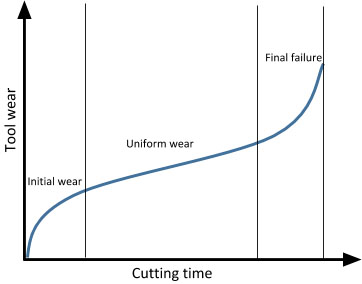

It is not just programming, but considering the tool contact time and wear we need to modify the program to avoid operator intervention, improved insert life, zero accidents and optimum cycle time.

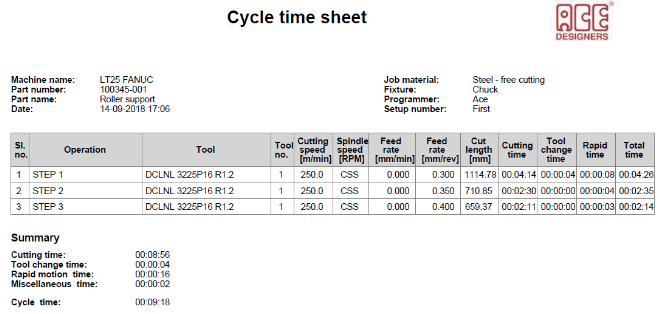

Considering above graph we will take one example of long contact time component.

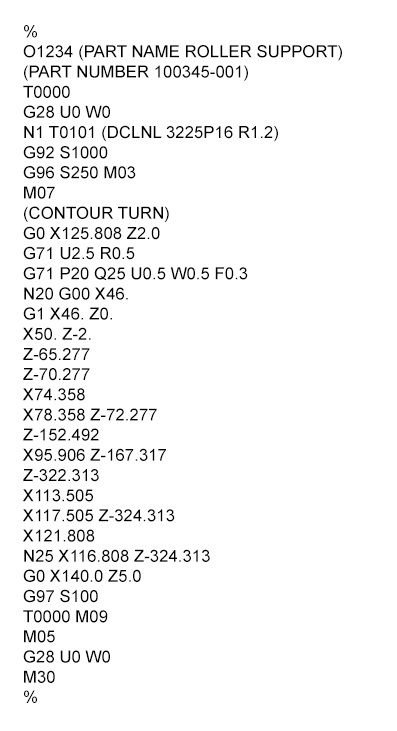

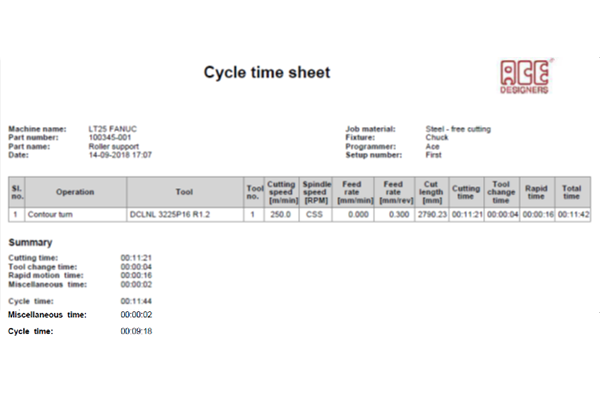

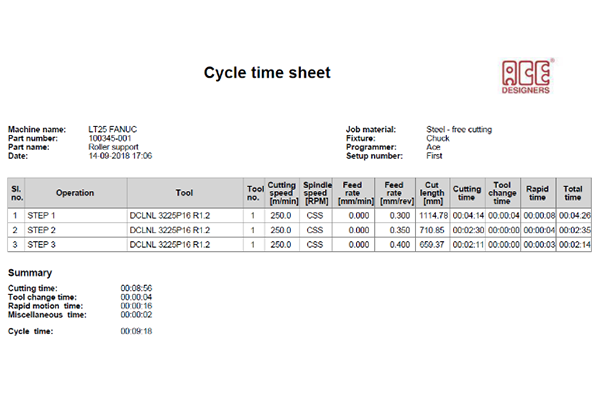

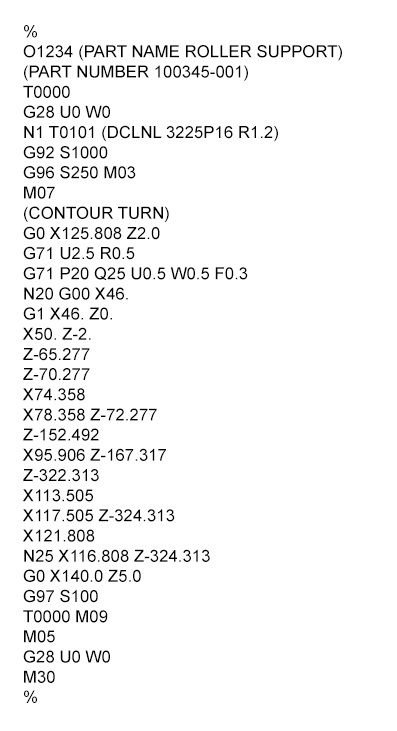

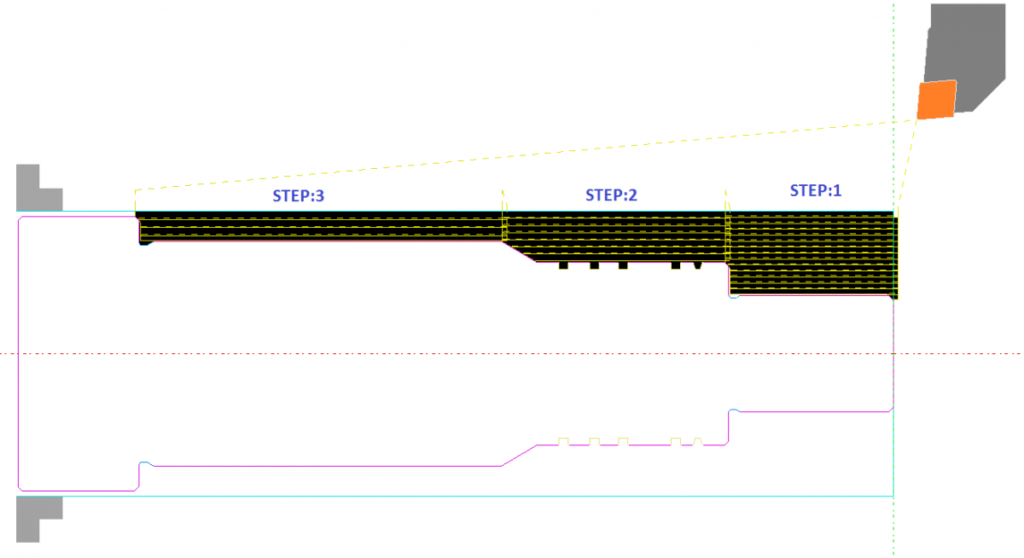

Regular programming method/cycle:

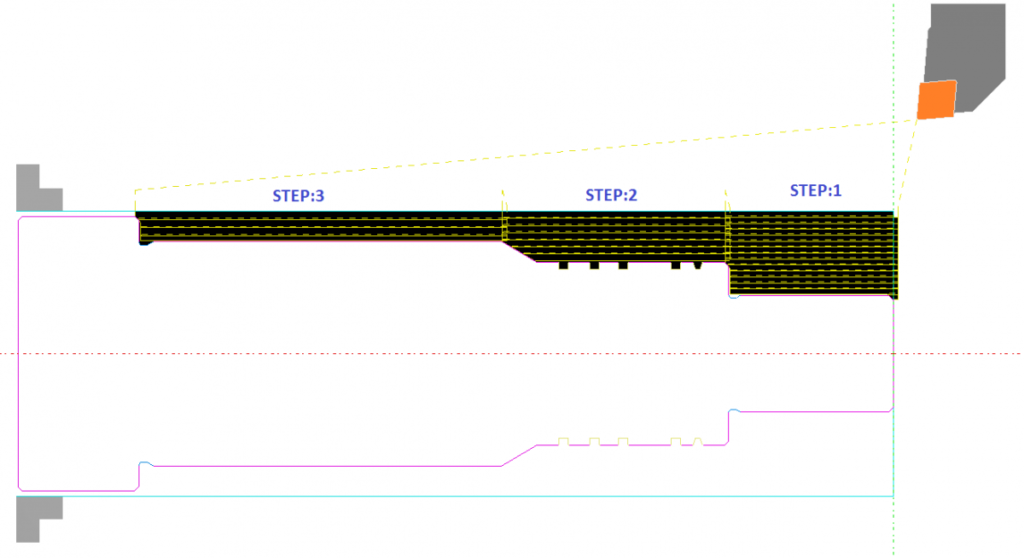

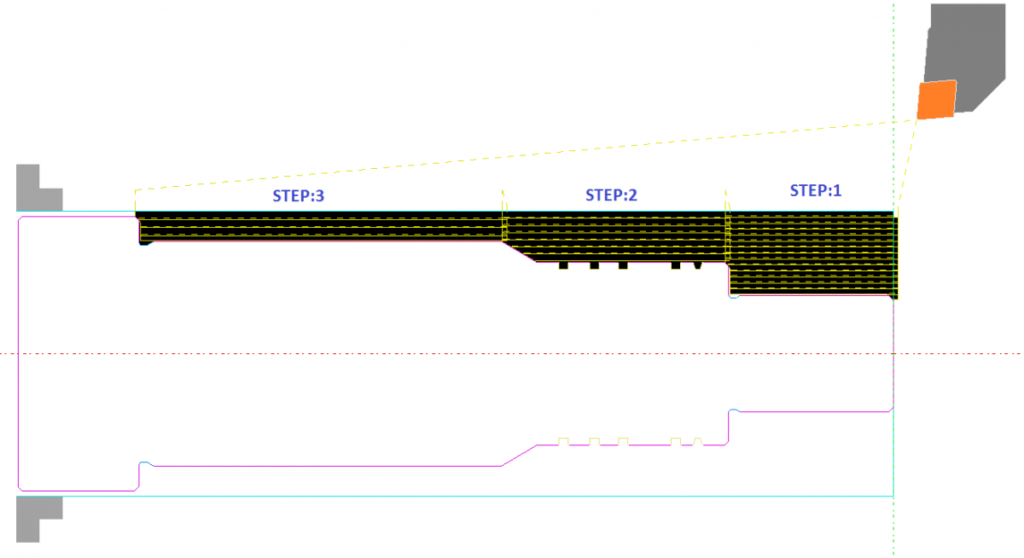

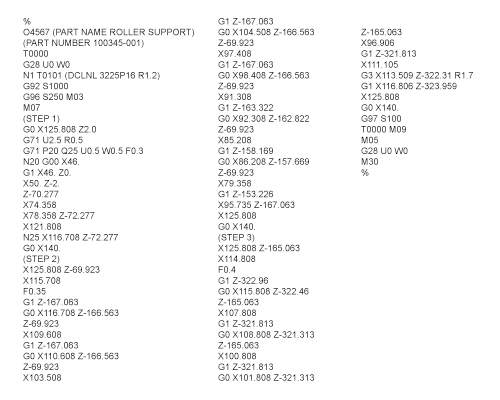

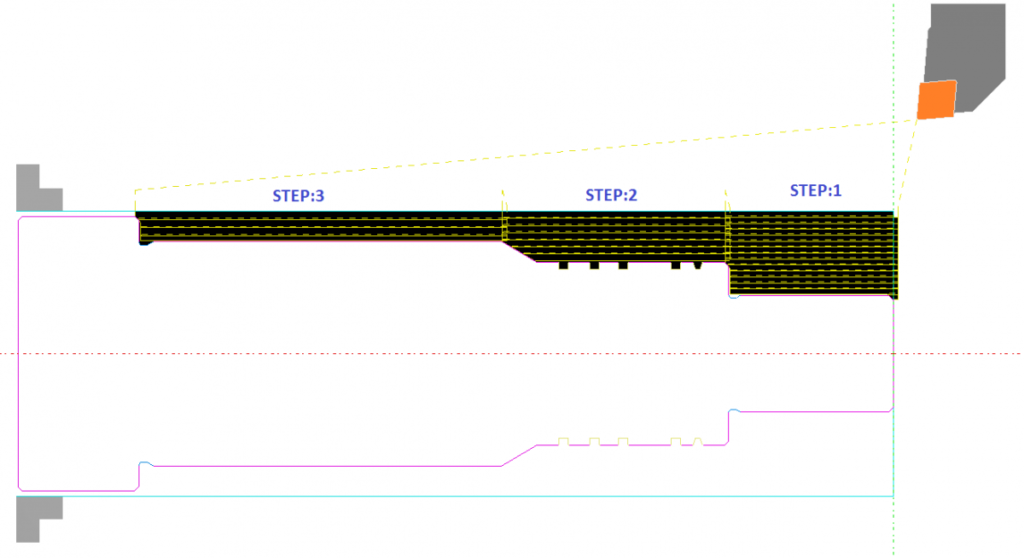

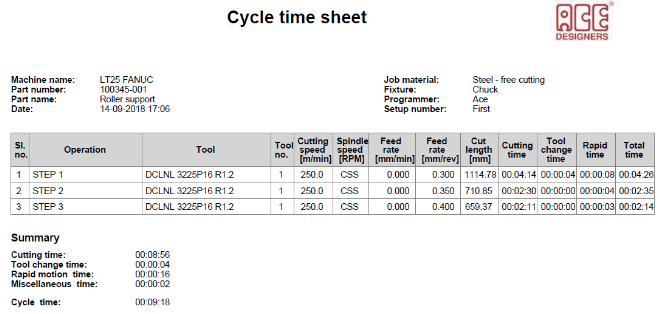

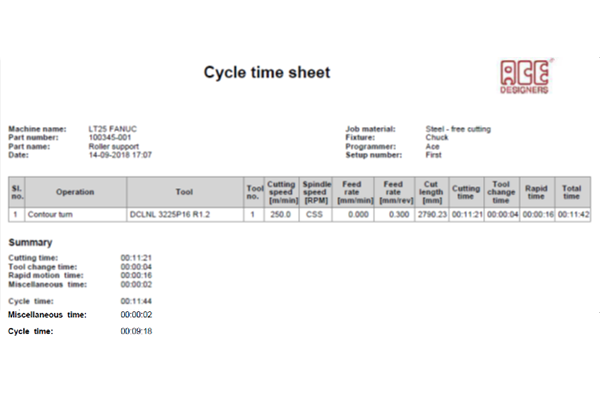

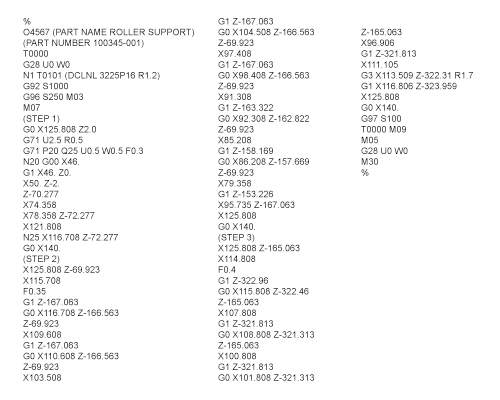

Modified method:

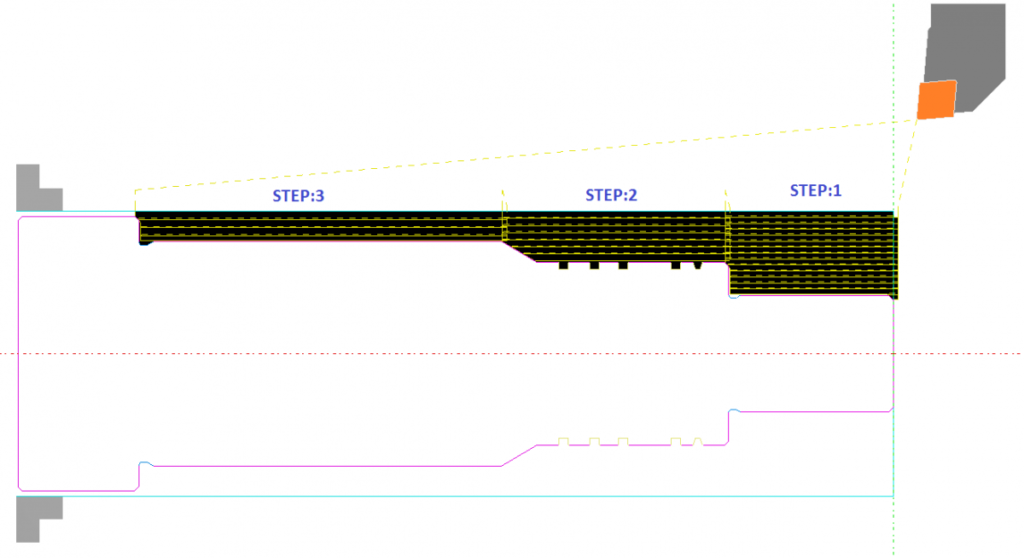

As the tool move towards spindle, depth of cut and feed rate can be increased keeping cutting speed constant. This will help us to reduce cycle time and number of cutting passes.

Dividing the total length in to number of steps, will help us to:

- Reduce insert contact time

- Easy chip evacuation

- Increased insert life

- Every subsequent STEP we can increase cutting parameter

Summary:

- Long contact length

- Reduced insert life

- Possibility of insert breakages because of long contact time and chip winding if chip do not break

- L/D will increase after every cut

- Not advisable to use optimum cutting parameters (Vc, Depth of cut & Feed)

- Higher cycle time

- Increased operator intervention for chip removing, insert replacement

- Increased down time

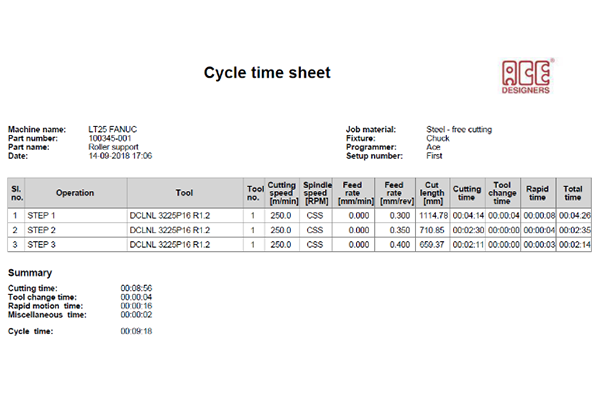

- Cycle time: 11.47 min

- Shorter contact length

- Increased insert life

- Because of short contact length insert will not get in to failure state, chip accumulation will be less

- L/D will decrease after every cut, will enable us to use increased parameters

- Cutting parameters (Vc, Depth of cut & Feed) can varied suitably

- Reduced cycle time

- Less operator intervention for chip removing, insert replacement

- Reduced down time

- Cycle time : 9.18 min

India

India

China

China

Europe

Europe

As the tool move towards spindle, depth of cut and feed rate can be increased keeping cutting speed constant. This will help us to reduce cycle time and number of cutting passes.

Dividing the total length in to number of steps, will help us to:

As the tool move towards spindle, depth of cut and feed rate can be increased keeping cutting speed constant. This will help us to reduce cycle time and number of cutting passes.

Dividing the total length in to number of steps, will help us to: