Automation is the inevitable future of manufacturing. While some misconceptions about the technology are stopping the faster adaptation of it, the benefits provide a unanimous verdict on how much it elevates the business of metal cutting.

From everyday commodities to machine tools, buying locally/domestically made products are a great decision.

Here are six reasons supporting the claim.

Financials:

- Faster ROIAutomation solutions can recover and even fund themselves rapidly due to lower factors like reduced lead times, operating costs, better output, and a lot more.

- Low operating costsWith the obvious savings on the cost of labor, Additional areas where money can be saved are in energy consumptions due to lower heating requirements. Automation focuses on processes and increases part accuracy, which means marginal material waste for your operation.

Efficiency:

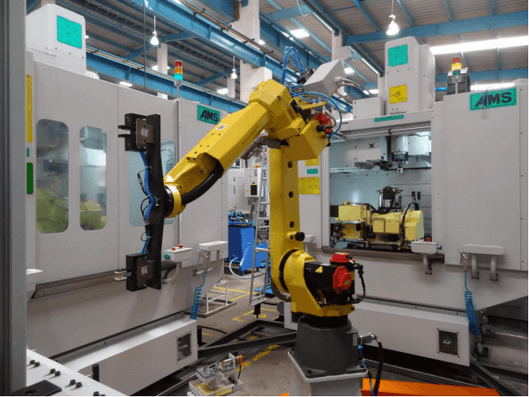

- A robot can work at a constant speed, unsupervised, around the clock. That means you’ve got the potential to produce more. New products can be more quickly introduced into the production process and new product programming can be done offline with no disruption to existing processes.

- Decreased lead timesAutomation helps keep your process in-house, improve process control. This pays back better than outsourcing production which also saves on time and significantly reduces lead times compared to outsourcing or going overseas.

- Increase productivity and efficiencyAutomated cells can be IoT integrable which provides important insights into production. They can work 24/7 , perform secondary operations like gauging, deburring etc. Easily integrated to varying requirements are all key points that make Automated cells so productive.

- LaborSafer work environment - Automated cells protects operators from dangerous tasks. Your workforce is an asset, safeguarding them and using their talents efficiently on other tasks will be a smart move.

- Optimum usage of laborThe trend for the future is that labor will be a hard thing to come by. On wait for things to get desperate before switching to Automation.

- Production:

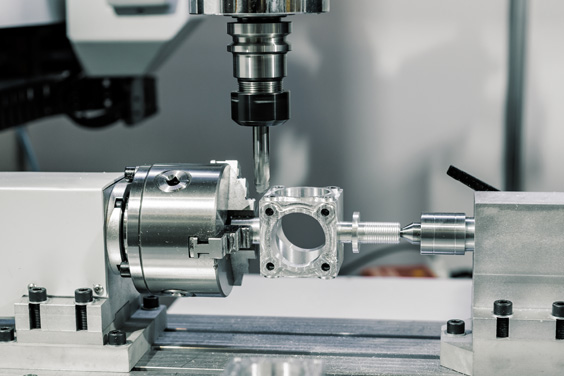

Offer competitive services - Automated cells allow you to decrease cycle times and cost-per-piece while improving quality. This allows for upping your chances of giving a good offer compared to your contemporaries.

- Improved quality and consistencyAutomated cells typically perform the manufacturing process with less variability than human workers. This results in greater control and consistency of product quality.

- Reduce the need for outsourcingBecause automated systems are versatile and highly capable, the need to outsource work will not make sense since it is cheaper, faster, and better to do these processes in-house.

Spacing:

- Compact footprintBy streamlining equipment and processes, reducing scrap and using less space, automation uses less energy. Reducing your environmental footprint can save real money.

- Optimal utilization of floor spaceRobots are built to fit into small spaces. In addition to being mounted on the floor, robots can be mounted on walls, ceilings, rail tracks and shelves. They can perform tasks in confined spaces, saving you valuable floor space.

Future ready:

- Easy to integrateYour cell will be proven out at productivity and shipped production-ready – allowing you to start making parts as soon as it’s installed in your shop. Productivity will work with you to provide a complete system – hardware, software and controls included.

- Versatile system:Robots are very flexible and can be programmed to suit any process. Benefits like ability to handle varying size of components, adaptability to different or new processes, quick change-overs are instrumental making work substantially easier.

India

India

China

China

Europe

Europe